Auburn’s ARC program was founded in 2009, and over the last decade has become the universal language for identifying and communicating passive UHF RFID inlay requirements across the RFID ecosystem. ARC has assisted dozens of end users in a variety of industries including but not limited to retail, aviation, manufacturing, and transportation through the process of selecting RFID tags that meet the performance standards for their projects. Technology providers have used ARC Specs to create and deliver innovative products that meet existing use cases and enable new applications. It has provided technology companies a scalable/reliable way to understand and verify tag performance against the performance requirement of the end users.

As the market has expanded and matured to over 10 billion passive UHF tags per year, quality manufacturing of the tags has become equally as important to performance. Simply put, in any use case first we must prove that an RFID tag model will scan (performance), then we must prove that the tag manufacturer can consistently make millions of them that will continue to deliver the same performance (quality).

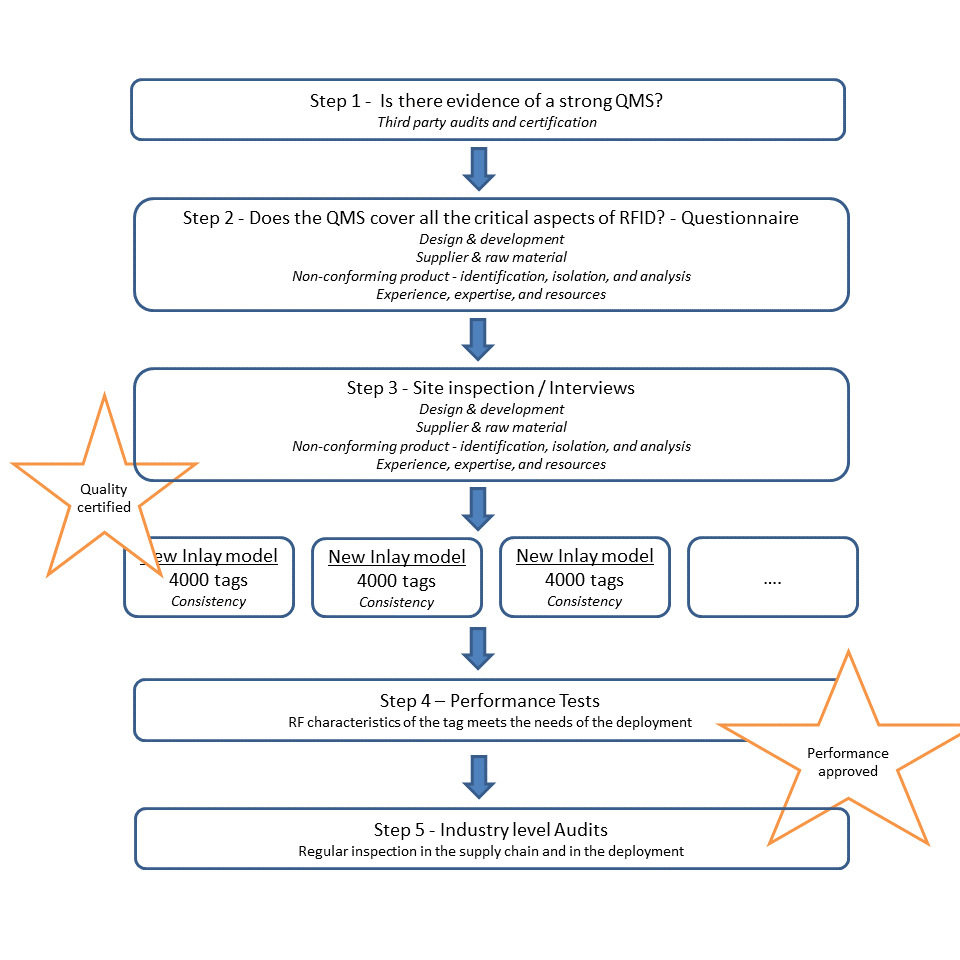

ARC Quality certification ensures that the tag manufacturer has a well implemented QMS that covers all the critical aspects of design and manufacture of RFID tags. Building on industry standard quality manufacturing certification practices of ISO and other standards organizations, the ARC Quality Certification Program does not impose an external quality management system, but instead audits the internal QMS practices of inlay manufacturers in a multi-step review process, including site visits. The program publicly validates that the inlay manufacturer has the experience, expertise, and resources to ensures that the performance of tags are sustained and delivered over time and volume.

Arizon

Avery Dennison Smartrac

Checkpoint

Hana

LAB ID – Beontag

Paragon ID

SML

Tageos